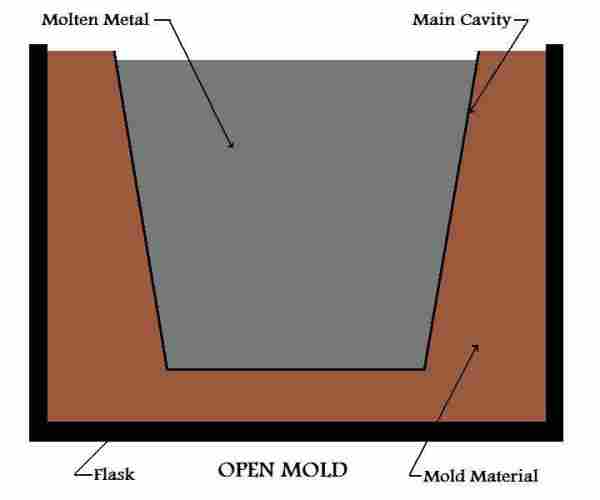

A cookware mold is formed into the geometric shape of a desired part. Molten metal is then poured into the mold, the mold holds this material in shape as it solidifies. A cookware casting is created. Although this seems rather simple, the manufacturing process of metal casting is both a science and an art. Let’s begin our study of metal casting with the mold. First, molds can be classified as either open or closed. An open mold is a container, like a cup, that has only the shape of the desired part. The molten material is poured directly into the mold cavity which is exposed to the open environment.

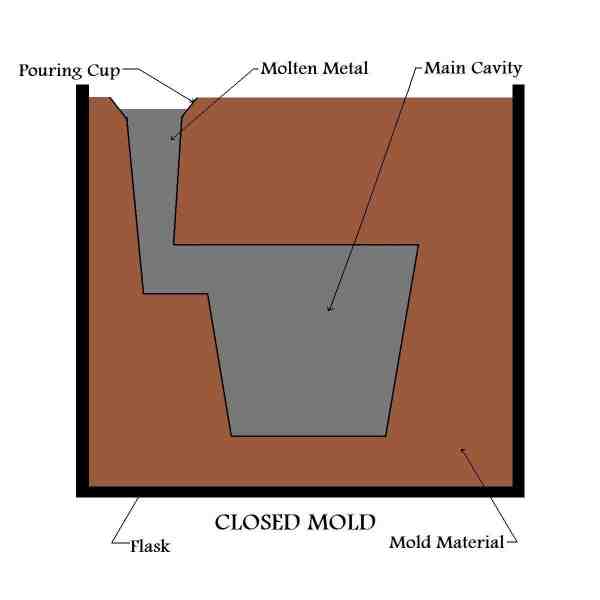

This type of mold is rarely used in manufacturing production, particularly for metal castings of any level of quality. The other type of mold is a closed mold, it contains a delivery system for the molten material to reach the mold cavity, where the part will harden within the mold. A very simple closed mold is shown in figure 2. The closed mold is, by far, more important in manufacturing metal casting operations.

This type of mold is rarely used in manufacturing production, particularly for metal castings of any level of quality. The other type of mold is a closed mold, it contains a delivery system for the molten material to reach the mold cavity, where the part will harden within the mold. A very simple closed mold is shown in figure 2. The closed mold is, by far, more important in manufacturing metal casting operations.

Expendable MoldCan produce one metal casting only

Made of sand, plaster, or other similar material

Binders used to help material hold its form

Mold that metal solidifies in must be destroyed to remove casting

More intricate geometries are possible for casting

Permanent MoldCan manufacture many metal castings

Usually made of metal or sometimes a refractory ceramic

Mold has sections that can open or close, permitting removal of the casting

Need to open mold limits part shapes

Patterns:

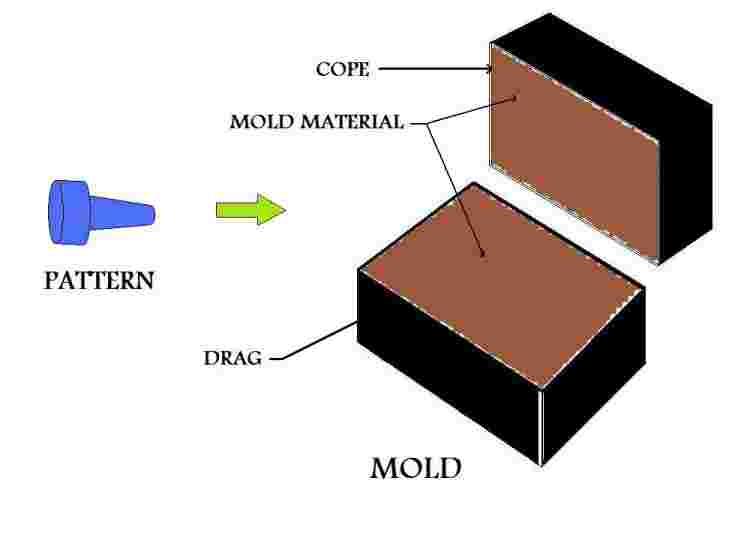

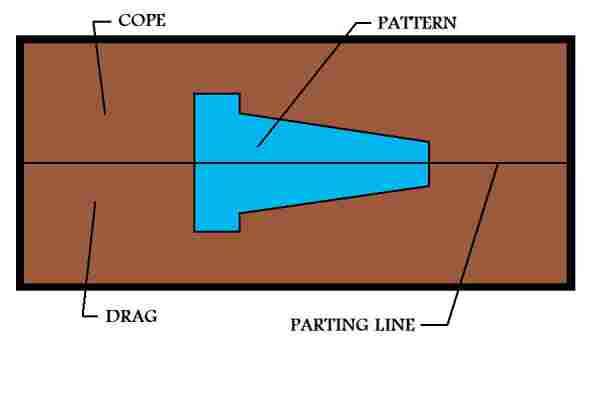

Expendable molds require some sort of pattern. The interior cavities of the mold, in which the molten metal will solidify, are formed by the impression of this pattern. Pattern design is crucial to success in manufacture by expendable mold metal casting. The pattern is a geometric replica of the metal casting to be produced. It is made slightly oversize to compensate for the shrinkage that will occur in the metal during the casting’s solidification, and whatever amount of material that will be machined off the cast part afterwards. Although machining will add an extra process to the manufacture of a part, machining can improve surface finish and part dimensions considerably. Also, increasing the machine finish allowance will help compensate for unknown variables in shrinkage, and reduce trouble from areas of the metal casting that may have been originally too thin or intricate.

Pattern Material:

The material from which the pattern is made is dependent upon the type of mold and metal casting process, the casting’s geometry and size, the dimensional accuracy required, and the number of metal castings to be manufactured using the pattern. Patterns can be made from wood, like pine (softwood), or mahogany (hardwood), various plastics, or metal, like aluminum, cast iron, or steel. In most manufacturing operations, patterns will be coated with a parting agent to ease their removal from the mold.

Cores:

For metal castings with internal geometry cores are used. A core is a replica, (actually an inverse), of the internal features of the part to be cast. Like a pattern, the size of the core is designed to accommodate for shrinkage during the metal casting operation. Unlike a pattern, a core remains in the mold while the metal is being poured. Hence, a core is usually made of a similar material as the mold. Once the metal casting has hardened, the core is broken up and removed much like the mold. Depending upon the location and geometry of the core within the casting, it may require that it is supported during the operation to prevent it from moving or shifting. Structural supports that hold the core in place are called chaplets. The chaplets are made of a material with a higher melting temperature than the casting’s material, and become assimilated into the part when it hardens. Note that when manufacturing a metal casting with a permanent mold process, the core will be a part of the mold itself.

The Mold:

A typical mold is shown in figure 3.

Elements Of A Gating System:

Pouring Basin:

This is where the molten metal employed to manufacture the part enters the mold. The pouring basin should have a projection with a radius around it to reduce turbulence.

Down Sprue:

From the pouring basin, the molten metal for the casting travels through the down sprue. This should be tapered so its cross-section is reduced as it goes downward.

Sprue Base:

The down sprue ends at the sprue base. It is here that the casting’s inner cavity begins.

Ingate/Choke Area:

Once at the sprue base, the molten material must pass through the ingate in order to enter the inner area of the mold. The ingate is very important for flow regulation during the metal casting operation.

Runners:

Runners are passages that distribute the liquid metal to the different areas inside the mold.

Main Cavity:

The impression of the actual part to be cast is often referred to as the main cavity.

Vents:

Vents help to assist in the escape of gases that are expelled from the molten metal during the solidification phase of the metal casting process.

Risers:

Risers are reservoirs of molten material. They feed this material to sections of the mold to compensate for shrinkage as the casting solidifies. There are different classifications for risers.

Top Risers: Risers that feed the metal casting from the top.

Side Risers: Risers that feed the metal casting from the side.

Blind Risers: Risers that are completely contained within the mold.

Open Risers: Risers that are open at the top to the outside environment.

2 Responses

You need to be a part of a contest for one of the best blogs on the net. I will highly recommend this blog!

I need to to thank you for this very good read!! I certainly loved every little bit of it. I have you book-marked to check out new things you postÖ